In June 2025, through in-depth communication and technical evaluation, a famous new energy engineering company in Argentina finally purchased 4 sets of solar pile driver for sale from YG Machinery for a 100MW ground-mounted photovoltaic power plant project in San Juan province. This cooperation not only demonstrates the reliable strength of Chinese manufacturing, but also reflects the broad prospect of Argentina’s new energy market.

YG Solar Pile Driver Machine Parameters

| Hydraulic photovoltaic pile driver | |||

| Overall dimensions | 4700*2100*2800mm | Drill pipe rotational speed | 180r/min |

| Track shoe width | 400mm | gradability | 30° |

| motor | 4108 | rock hardness | 6-20F |

| Drilling diameter | 80-500mm | Slide tilt angle | 120° |

| Drilling depth | 0-6m | Drill arm swing angle | left and right150° |

| Reducer torque | 13000n.m | Slide swing angle | left and right40° |

| Mainstream pump | triple pump | Driving speed | 0-3km/h |

| oil pump | 40/40/32 | ||

| Crawler photovoltaic pile driver | |||

| Overall dimensions | 4700*2200*2800mm | Hydraulic hammer flow | 50-110L/min |

| Track shoe width | 400mm | Impact frequency | 350-800BMP |

| motor | 4108 | Hydraulic system pressure | 25mpa |

| Generator power | 88kw Motor | Strong wind for heat dissipation | yes |

| Drilling depth | 0-6m | oil pump | 40/40/32 |

| Drilling diameter | 80-600mm | Driving speed | 3km/h |

Argentina’s PV Market Status: Wide Land and Strong Light, Positive Policies

In recent years, the Argentine government has actively promoted the development of renewable energy, especially solar power projects. According to IRENA data, as of 2024, Argentina’s installed capacity of PV has exceeded 2GW, and is still growing rapidly, mainly concentrated in the western provinces with abundant sunshine resources (such as Mendoza, San Juan, Hu Huy).

The characteristics are as follows:

- Wide and sparsely populated, suitable for large-area ground power plant construction;

- complex terrain, dominated by mountains, sandy and arid hard lands;

- high labor cost and strong demand for mechanized construction;

- Tight project promotion cycle and high efficiency requirements for construction equipment.

Client Background and Project Requirements

The client is an important PV EPC contractor in the western region of Argentina, and has constructed several medium and large solar farms. For this 100MW project in San Juan province, the piling workload is expected to exceed 65,000 piles, which needs to be completed within 90 days.

The core requirements set forth by the client included:

- Efficient construction: no less than 400 piles per day for a single machine;

- Multi-terrain adaptability: adapting to sand, hard soil, gravel and other complex terrain;

- High temperature resistance and dustproof design, adapt to local dry and hot climate;

- Provide a complete set of technical support and after-sales training.

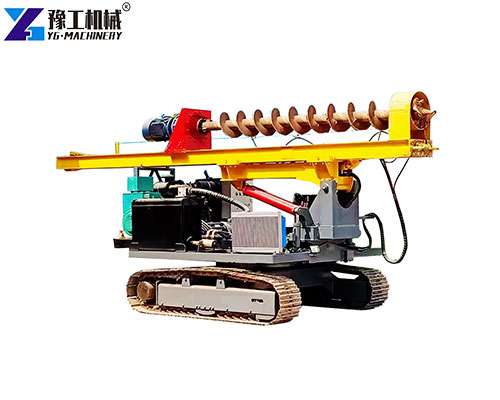

YG Recommended Solution: 4 High-efficiency Solar Pile Driver Machines

According to the customer’s needs and the project field environment, YG team recommends 4 tracked solar pile driver machines equipped with high frequency hydraulic hammers, which have the following advantages:

- Power system: diesel driven, stable and reliable.

- Crawler chassis: strong off-road ability, adapting to mountain and sandy land.

- Hydraulic Piling Hammer: high impact frequency, fast driving into hard soil and gravel.

- Pile length compatibility: support 2-4 meters steel piles.

These equipments not only meet the requirements of high-intensity continuous construction, but also can be deployed and operated in different areas at the same time, significantly shortening the overall construction cycle.

The Key Role of PV Pile Driver in the Whole Construction Process

In the construction process of PV power plant in Argentina, piling is the basic link of bracket installation, which determines the stability of the overall structure of the power plant and the efficiency of module placement in the later stage.

📌 Unstable piling ➝ Skewed racking ➝ Angle deviation of panels ➝ Decrease in power generation efficiency

📌 Unfastened piling ➝ Delayed project ➝ Increase in management and labor costs

Therefore, the customer pays special attention to the high-efficiency photovoltaic piling solution and is willing to focus on purchasing multiple photovoltaic pile drivers in the pre-construction stage to realize fast progress.

Customer Feedback and Field Performance

4 sets of pv pile driver arrived at the project site in Argentina at the end of June, and after remote video guidance and local operation training by YG technical engineers, the equipment was successfully put on line for operation.

Operation effect data feedback:

- Average daily piling volume: 480 piles/unit.

- Average piling time per pile: about 50 seconds.

- The accuracy is controlled within ±10mm.

- The equipment runs stably, the fuel consumption is lower than the estimated value by 10%.

Customer feedback: “The construction efficiency of this batch of solar pile driver machine is very high, which has far exceeded that of the European and American brand equipment we used in the past, and the after-sale response is fast, and the cost-effectiveness is also very outstanding.”

Solar Pile Driver for Sale in YG Machinery

The one-time large-volume purchase by the Argentinean customer once again verifies the competitiveness and technical maturity of YG brand in the field of global PV foundation construction equipment. Under the trend of accelerated development of global PV, choosing a suitable solar pile driver for sale means choosing shorter construction period, higher efficiency and more stable income. In addition, we also produce crawler solar pile driver machine, DTH drilling rig, rotary drilling rig and so on.

If you are from Latin America, the Middle East, Africa and other regions with abundant light resources, and are looking for PV pile driver or photovoltaic pile driver for local projects, welcome to contact YG for one-on-one selection advice and latest price!【WhatsApp/WeChat/Phone】+86 13837115193.