In early 2025, a construction company based in Lima, Peru, contacted YG Machinery to inquire about a boom pump truck for sale. The client, specializing in residential and road infrastructure projects, had faced repeated delays due to inefficient concrete pouring equipment. Traditional line pumps and manual labor could not handle large-scale projects with high precision requirements. After extensive market research, the company chose YG’s advanced boom pump truck for its superior reach, stable performance, and reliable after-sales service.

Boom Pump Truck Parameters

| Vehicle model | / | 5230THB | |

| whole vehicle | Dimensions: length x width x height | mm | 9500X2500X3680 |

| Vehicle weight | Kg | 23000 | |

| Pumping | Concrete theoretical delivery | m³/h | 60 |

| Concrete theoretical output pressure | MPa | 10 | |

| Hopper volume | m³ | 0.6 | |

| Feeding height | mm | 1450 | |

| Maximum aggregate size | mm | 40 | |

| Concrete slump | mm | 120-230 | |

| Approach angle/departure angle | (°) | 19°/11° | |

| Hydraulic | Hydraulic system pressure | MPa | 32 |

| Hydraulic circuit (open/closed type) | / | open | |

| Hydraulic oil tank capacity | L | 600 | |

| Lifting arm | Maximum vertical fabric height | m | 30 |

| Maximum horizontal fabric radius | m | 28 | |

| Maximum fabric depth (including 3m hose) | m | 22 | |

| Lifting arm folding method | / | RZ | |

| Minimum boom extension height | mm | 6200 | |

| Length of each section of the boom | mm | 7550/6300/6300/3455/2856 | |

| Rotating angle of each section of the boom | (°) | 90/180/180/245/90 | |

| Angle of rotation | (°) | ±360º | |

| Tail hose length | m | 3 | |

| Support leg | Longitudinal span of outrigger | mm | 6200 |

| Transverse span of front outrigger | mm | 5300 | |

| Rear leg transverse span | mm | 5300 | |

Product Specifications and Technical Highlights

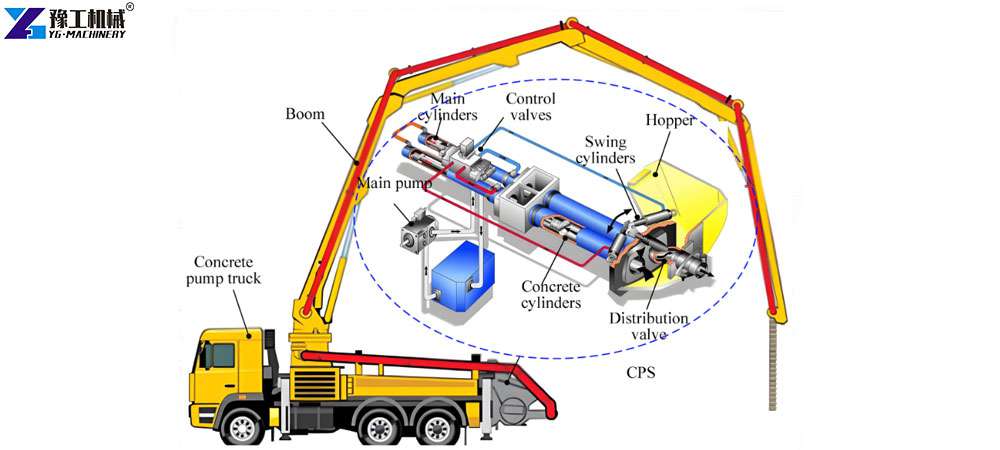

The purchased unit was a 40-meter model equipped with a 200mm delivery cylinder and a 2m³ mixing capacity. It uses a powerful 85 kW diesel engine and a fully hydraulic system to ensure smooth and continuous pumping. The maximum output capacity reaches 40m³/h, meeting most mid- to large-scale construction needs. Mounted on a tracked all-terrain chassis, the truck easily operates on uneven sites common in Peru’s hilly regions. The total weight of the equipment is 17 tons, with a self-weight of 11.5 tons.

The boom system features five sections with a 360-degree rotating arm, offering flexible coverage for both vertical and horizontal pouring. Operators appreciated the remote-control system, which allowed them to adjust flow and direction precisely, reducing concrete waste. The intelligent hydraulic control system automatically regulates pressure, preventing blockages and ensuring safety even under long pumping durations.

Growing Demand for Boom Pump Trucks in Peru

In recent years, Peru’s construction industry has experienced steady growth due to government investments in housing and infrastructure. However, limited availability of efficient concrete placement equipment has slowed progress in many rural and mountainous areas. Local contractors often struggle with narrow roads and challenging terrains that make traditional equipment hard to deploy.

This is where the need for a boom pump truck for sale becomes evident. Its self-contained design combines pumping, mixing, and conveying functions in one compact unit. Unlike stationary pumps, it does not require additional transportation or installation time. It can reach heights of up to 15 meters and deliver concrete directly where it’s needed, even across complex job sites. The mobility and efficiency of these machines have made them an essential part of Peru’s growing construction landscape.

Solving Customer Pain Points Through Innovation

Before purchasing from YG, the Peruvian client had been using older truck mounted pump systems that required frequent manual adjustments and maintenance. Workers often needed to reposition the machinery multiple times during each project, wasting both time and materials. In mountainous regions near Cusco and Arequipa, transporting concrete over rough terrain became nearly impossible using traditional pumps.

YG Machinery’s customized solution directly addressed these challenges. The boom arm’s extended reach allowed operators to deliver concrete over long distances and high elevations without relocating the vehicle. The fully hydraulic stabilizers ensured balance and safety during operation, even on sloped surfaces. The customer reported that the new unit improved construction efficiency by nearly 35% while cutting labor costs by 25%.

Application Scenarios and On-Site Performance

The new unit was first deployed in a housing development project on the outskirts of Lima. It successfully poured foundations for 60 houses in less than two weeks—a task that would normally take over a month using standard equipment. Later, it was transferred to a bridge repair project along the Pan-American Highway, where its long arm provided precise concrete placement for deck reconstruction.

Operators praised its user-friendly interface and remote control features, which allowed easy maneuvering in tight urban zones and rugged areas. Compared with a long boom concrete pump used previously, this model required less fuel and maintenance, significantly reducing operational costs. The client’s team noted smoother pumping performance, fewer hose clogs, and improved safety standards on-site.

Customer Feedback and Industry Insights

After three months of continuous operation, the Peruvian client shared detailed feedback with YG Machinery. “This equipment completely changed how we approach concrete work,” said the project manager. “The precision and stability allow us to complete projects faster and with fewer workers. We’re now planning to purchase another boom truck concrete unit for our new site in Trujillo.”

Such testimonials highlight how modern construction projects in South America increasingly rely on high-performance concrete delivery systems. The shift toward integrated and automated machinery reflects the global trend of improving job site productivity and reducing human error. For many medium-sized contractors, these machines provide an ideal balance between mobility, affordability, and efficiency.

Boom Pump Truck for Sale in YG Machinery

YG Machinery has over a decade of experience in designing and manufacturing high-quality construction equipment. Each boom pump truck undergoes strict testing before shipment to ensure performance stability and long-term reliability. YG’s after-sales team provides comprehensive support, including installation guidance, remote troubleshooting, and spare parts supply. In addition, YG also produces crawler-type long-arm concrete pumps that are more suitable for complex terrains, as well as portable trailer concrete pumps, etc. Contact us to know more details now!【WhatsApp/WeChat/Phone】+86 13837115193.

Clients worldwide choose YG because of its flexible customization options, competitive pricing, and commitment to innovation. The company’s goal is to help customers achieve higher productivity while minimizing downtime. For the Peruvian client, these advantages translated into faster project turnover, lower costs, and stronger client satisfaction.