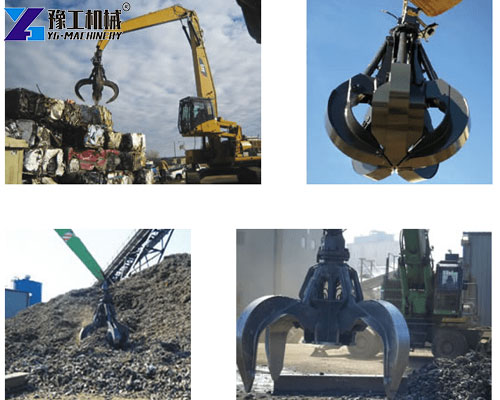

Scrap grabs, also known as orange peel grapples, are essential tools for industries dealing with bulk materials, scrap metal, and debris. These hydraulic attachments are mounted on cranes, excavators, or material handlers, offering powerful control for handling irregular materials with ease and precision. In this article, we’ll dive into the technical specifications, applications, advantages, and maintenance tips for scrap grabs, while showcasing how YG Machinery provides robust and reliable solutions for businesses worldwide.

Scrap Grab Parameters

The scrap grab, or orange peel grapple, comes in different sizes and configurations to meet various material handling needs. YG Machinery offers a wide range of models that suit different excavator capacities, with an emphasis on hydraulic performance, durability, and high efficiency. Below are the key parameters for YG’s most popular scrap grabs:

| Item/Model | Unit | YGO04A | YGO06A | YGO08A | YGO06B | YGO08B |

| No. of Jaw | piece | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 |

| Suitable Excavator | ton | 6-9 | 10-17 | 18-25 | 10-17 | 18-25 |

| Weight | kg | 355/420 | 900/1000 | 1650/1900 | 850/1000 | 1700/1950 |

| Max Open Jaw | mm | 1200 | 1600 | 2050 | 1900 | 2500 |

| Height of Opened Grapple | mm | 1000 | 1500 | 1700 | 1550 | 2000 |

| Working Pressure | bar | 200 | 260 | 320 | 260 | 320 |

| Working Flow | lpm | 50-100 | 60-120 | 200-250 | 60-120 | 200-250 |

| Capacity | m3 | 0.3 | 0.4 | 0.8 | 0.5 | 1 |

These parameters demonstrate the variety of sizes and capacities available, ensuring that businesses can find a suitable model depending on their material handling requirements and machine compatibility.

Scrap Grab Applications

The versatility of scrap grabs makes them invaluable in a range of industries where efficient handling of bulk materials is required. Here are some key applications:

- Scrap Metal Handling: Ideal for lifting and sorting scrap metal at recycling yards and scrap processing plants.

- Construction and Demolition: Perfect for grabbing debris and separating materials at demolition sites, improving cleanup efficiency.

- Waste Management: Widely used in landfill and recycling facilities for transporting waste and recyclable materials, ensuring swift operations.

- Forestry and Agriculture: These grapples are also effective in handling logs, branches, and other forestry debris.

- Port and Dock Operations: Used for loading and unloading bulk materials like coal, gravel, and other loose materials in ports.

Key Advantages of Using Scrap Grabs

Scrap grabs stand out for their robustness, precision, and adaptability. Some of the core advantages include:

- Fuel Efficiency: Compared to traditional material handling methods, hydraulic scrap grabs from YG Machinery have fuel efficiency that is up to 20% higher than the industry standard, significantly reducing operating costs.

- Hydraulic Rotation: Many models come with 360-degree hydraulic rotation, allowing operators to handle materials from different angles without repositioning the entire machine.

- Durability and Strength: The grab’s jaws are made from high-strength steel, designed to withstand harsh environments and heavy-duty tasks, providing reliable performance even in challenging conditions.

- Improved Productivity: With high-speed operations and secure handling, scrap grabs can increase material handling efficiency by up to 30%, making them an essential tool for large-scale operations.

Maintenance and Care Tips for Scrap Grabs

Proper maintenance of your scrap grab is crucial for ensuring longevity and performance. Here are some essential tips:

- Regular Lubrication: Ensure that the hydraulic cylinders and moving parts are regularly lubricated to reduce wear and tear.

- Inspect Hydraulic Systems: Check hydraulic hoses and pumps for any signs of leakage or damage. Regularly test the pressure levels to maintain optimal function.

- Clean After Use: After each use, clean the grab to remove any accumulated dirt, rust, or debris, which can affect performance and lifespan.

- Jaw Inspection: Check the jaws regularly for cracks, wear, and corrosion. Replace or repair them if necessary to maintain efficient grabbing and handling capabilities.

- Store Properly: When not in use, store the scrap grab in a dry, sheltered area to protect it from environmental damage.

Customer Testimonials

Businesses worldwide have seen significant improvements in their material handling operations by using YG’s scrap grabs. One example includes a construction site in Jiangsu, where the efficiency increased by 30% after adopting the YGXX model.

Why Choose YG Scrap Grabs?

At YG Machinery, we pride ourselves on offering high-quality scrap grabs designed to meet the toughest demands of industries like construction, scrap metal recycling, and waste management.

If you’re looking for other attachments to complement your scrap grab, consider exploring these related products: hydraulic shears, hydraulic breakers, excavator quick couplers, excavator rock saws, mini excavator, electric stacker lift, etc. Contact us to know more details now!【WhatsApp/WeChat/Phone/Skype】+86 13837115193.