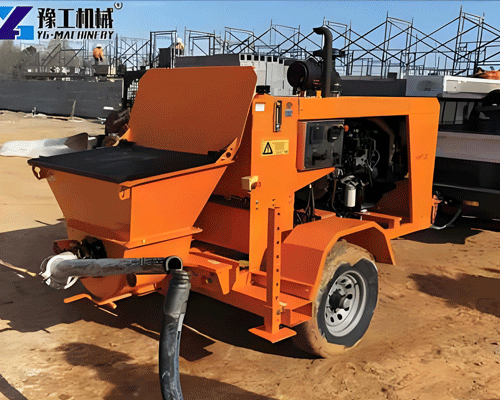

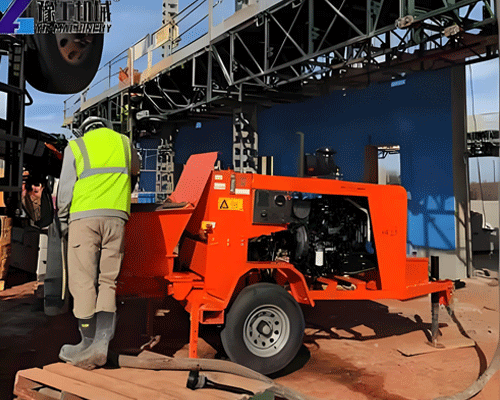

In compact construction sites, high-rise buildings, rural housing and other construction environments, it is difficult for large pump trucks to enter, while traditional manual operation is inefficient and costly. At this time, small concrete pump for sale is becoming the first choice equipment for small and medium-sized projects because of its convenience, flexibility and high efficiency. Looking for the latest small concrete pump price? Contact YG today for a free quotation. Reduce labor cost and improve on-site concrete delivery efficiency.

Mini Concrete Pump Machine Parameter

| Model | YG-20 | YG-30 | YG-40 | YG-50 |

| Motor power | 22KW | 37KW | 45KW | 55kw |

| Maximum outlet pressure | 26mpa | 28mpa | 28mpa | |

| Maximum theoretical throughput | 16-18m³/h | 20-22m³/h | 35m³/h | |

| The maximum particle size of aggregate | ≤20mm | ≤30mm | ≤40mm | |

| Vertical conveying distance | 40m | 80m | 120m | 150m |

| Horizontal conveying distance | 80m | 140m | 2600m | 300m |

| Diameter of conveying pipe | 80mm | φ80 (100) mm | φ100 (80) mm | Φ125/100mm |

| Whole machine weight | 1600kg | 2200kg | 2400kg | 2500kg |

| Dimensions | 3400x1200x1600mm | 3600x1500x1600mm | 4000x1500x1550mm | 4200*1700*1750mm |

When purchasing equipment, users are advised to give priority to the steel pipe conveying system. The steel pipe has stronger compression resistance, is not easy to bend and deform, and is more durable in high-frequency construction environment. Although the hose is easy to bend, it has a large pressure loss and is easy to age during long-distance transportation, so it is suitable for short-section supplementary use.

Cost-Effective & Intelligent Mini Concrete Pump Solutions

Compared with large commercial concrete pump trucks, mini concrete pump price of small concrete pump for sale has obvious advantages. User feedback shows that this kind of products are cost-effective and suitable for small and medium-sized construction units with limited capital budget. There are many kinds of mini concrete pump machine circulating in the market, but most of them do not have electronic control system or precise pumping control function, while YG products are fully upgraded in efficiency and intelligent control.

For users who need flexible transition construction, YG also provides portable mini concrete pump, which is equipped with casters or small tracked chassis, which can be manually or mechanically towed to easily cope with complex site transshipment.

Customer Case

“We bought a YG mini concrete pump for a small residential project in Bangkok. The pump is compact, easy to operate, and delivers concrete smoothly to all corners of the site. It saved us both time and labor costs. The portable design allowed us to move the pump between floors without difficulty. Highly recommended! So we purchased a self-loading concrete mixer truck from YG Machinery to expand our business.” – Somchai P., Contractor from Thailand

Mini Concrete Pump Price – What You Really Pay For

The price of a small concrete pump depends on the actual working requirements of your project rather than a fixed standard configuration. At YG Machinery, we provide factory-direct mini concrete pump solutions, allowing customers to control costs while ensuring reliable pumping performance on-site.

Main factors affecting mini concrete pump price include:

- Pumping capacity and output model

- Power system configuration (electric or diesel)

- Conveying distance and pipeline setup

- Mobility options (portable wheels or tracked chassis)

- Application environment (residential, rural, commercial construction)

Compared with large concrete pump trucks, YG small concrete pumps offer a much lower initial investment, reduced labor cost, and easier transportation between job sites. 👉 Contact YG today to get a factory-direct mini concrete pump price with a free technical solution.

FAQ about Small Concrete Pump

- What size projects is a small concrete pump suitable for?

Small concrete pumps are ideal for residential, commercial, and small to medium construction projects. They can efficiently deliver concrete for floors, small bridges, sidewalks, and garden foundations. - How much does a mini concrete pump cost?

The price of a mini concrete pump varies based on pump type, output capacity, and mobility features. YG provides factory direct pricing and customized solutions to meet your budget. - Can the pump handle long-distance or high-rise concrete delivery?

Yes, YG small concrete pumps, especially the portable and tracked models, are designed for flexible construction sites. They can pump concrete over moderate distances and heights, making them suitable for complex layouts. - Is the mini concrete pump easy to move and operate?

Absolutely. Portable mini concrete pumps come with casters or small tracked chassis, allowing manual or mechanical towing. They are designed for easy setup and efficient operation, even on tight construction sites.

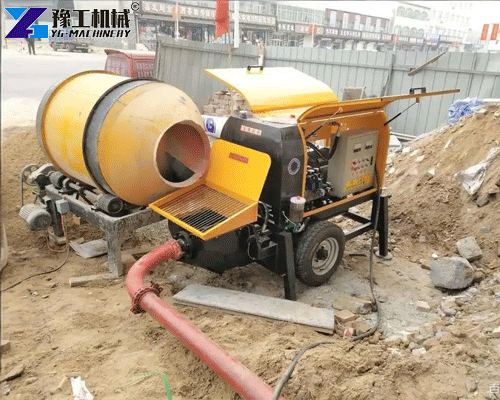

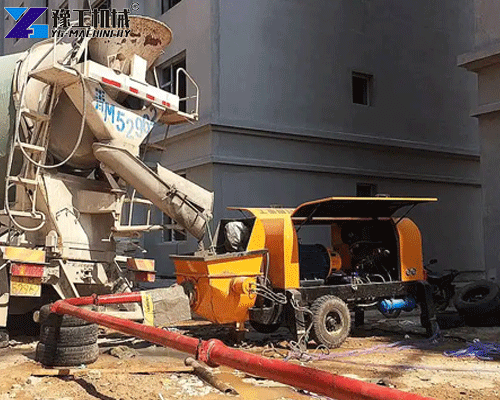

Expansion Scheme: Combined Application of Concrete Pump and Integrated Machine

For users with higher efficiency requirements, YG also provides an all-in-one concrete mixing and conveying machine. This kind of equipment is not simply the superposition of “concrete pump+conveyor belt”, but it integrates mixing, pumping and conveying, and has the ability of independent feeding, mixing and accurate pumping. Built-in roller or double-shaft mixing system can prepare concrete on site, which saves manual mixing and loading and unloading, improves the fluency of on-site operation, and is especially suitable for temporary engineering sites without the support of stable mixing station.

All-in-one machine is often equipped with high-power hydraulic system and thickened wear-resistant pumping elements, which supports long-term continuous operation and is an efficient tool for rural self-built houses, tunnel lining, slope stability and other projects.

Daily Maintenance Suggestions

In order to ensure the long-term stable operation of the equipment, users are advised to change the hydraulic oil regularly, check the wear of seals, and clean up the residual concrete in the S pipe and hopper. During use, idling or dry pumping in the pumping channel is strictly prohibited, and the operator needs to start and stop gradually according to the process to prevent parts from being damaged due to instantaneous pressure recoil.

For construction in low temperature environment in winter, the system should be preheated in advance to prevent the high viscosity of hydraulic oil from affecting the loop response. During shutdown, the whole machine should be cleaned, the system emptied, coated with antirust grease and properly sealed.

YG Machinery: A Reliable Manufacturer

As a professional manufacturer of concrete machinery, YG Machinery provides cost-effective engineering solutions for customers all over the world with rich export experience, strict quality control and perfect after-sales system. We not only have independent design team and modern production factory, but also have service points in many countries around the world to ensure timely response after sale.

For projects requiring on-site mixing and continuous pumping, an integrated concrete mixer with pump may be a better solution. Contact us now for free technical guidance and customized quotation! 【WhatsApp/WeChat/Phone/Skype】+86 13837115193.