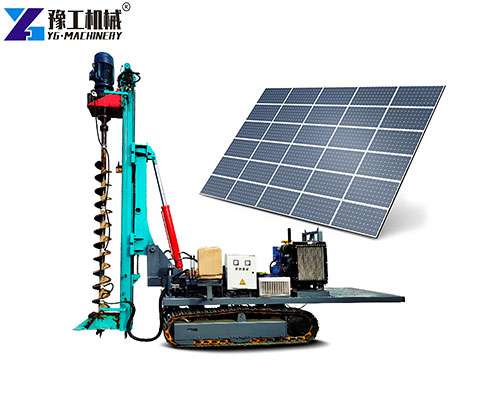

Don’t let slow piling and uneven terrain stall your solar projects or drain your budget. Our Solar Pile Driver can cut installation time by up to 30%, handle steep slopes and rocky grounds effortlessly, and keep your PV projects on schedule and under budget. Request a Free Quote now and start saving time and money today!

Solar Pile Driver Parameters

| Hydraulic photovoltaic pile driver | |||

| Overall dimensions | 4700*2100*2800mm | Drill pipe rotational speed | 180r/min |

| Track shoe width | 400mm | gradability | 30° |

| motor | 4108 | rock hardness | 6-20F |

| Drilling diameter | 80-500mm | Slide tilt angle | 120° |

| Drilling depth | 0-6m | Drill arm swing angle | left and right150° |

| Reducer torque | 13000n.m | Slide swing angle | left and right40° |

| Mainstream pump | triple pump | Driving speed | 0-3km/h |

| oil pump | 40/40/32 | ||

| Crawler photovoltaic pile driver | |||

| Overall dimensions | 4700*2200*2800mm | Hydraulic hammer flow | 50-110L/min |

| Track shoe width | 400mm | Impact frequency | 350-800BMP |

| motor | 4108 | Hydraulic system pressure | 25mpa |

| Generator power | 88kw Motor | Strong wind for heat dissipation | yes |

| Drilling depth | 0-6m | oil pump | 40/40/32 |

| Drilling diameter | 80-600mm | Driving speed | 3km/h |

Advantages of Solar Pile Driver

- Rapid Installation: Helical piles allow for very fast foundation installation, eliminating the need for concrete curing time.

- Reduced Environmental Disturbances: Compared to traditional concrete piles, helical piles require almost no excavation or soil removal, resulting in a cleaner construction site and less disturbance to the land.

- High Stability: Helical piles have excellent pull-out resistance, resisting wind lift and providing reliable support for photovoltaic panel supports.

- Reusable/Removable: After the project is completed, the helical piles can be “screwed out” for reuse or removal, making them environmentally friendly.

- Versatile Application: Our piling machines can operate in various soil types (sand, clay, rock, etc.), making them suitable for complex and remote photovoltaic sites.

- Cost Savings: Eliminating the need for concrete pouring and curing saves on labor and material costs, while also shortening the construction cycle.

- Low Environmental Impact: The installation process of helical piles involves little or no vibration, minimizing impact on the ecological environment.

- Real-Time Quality Control: Torque monitoring during installation verifies the load-bearing capacity and depth of each pile.

Customer Case Studies

Our Solar Pile Driver has been widely used in numerous projects worldwide, including photovoltaic power plants in complex terrains or with steep slopes. Whether on rocky ground, sandy soil, or slopes, our machines can reliably and efficiently complete piling tasks.

Colombia Project:

An EPC contractor in Bogotá, Colombia, installed a 500KW solar station over rocky slopes. Using our Telescopic Sliding Photovoltaic Pile Driver, the project finished 3 days ahead of schedule, saving over 25% on labor costs. The client said:

“It exceeded our expectations. The rotary speed, efficiency, and adaptability are impressive.”

Saudi Arabia Project:

A renewable energy company in Riyadh, Saudi Arabia, used our Solar Pile Driver for a 750KW solar farm on uneven desert terrain. The machine drilled continuously for 8 hours/day without overheating and handled slopes up to 45°. The client commented:

“This machine significantly improved our installation speed and reduced our overall project cost. Highly recommended for solar farms in harsh terrain.”

Frequently Asked Questions (FAQ)

Q: What pile diameters can this machine handle?

A: Supports 80–600 mm, customizable for project needs.

Q: Which terrains is it suitable for?

A: Slopes up to 45°, rocky ground, sand, and uneven terrain.

Q: How long is delivery/shipping time?

A: Typically 2 weeks; popular models are in stock.with worldwide shipping support.

Q: Do you offer after-sales service?

A: Yes, we provide global service support and spare parts availability.

Choose Professional Solar Pile Driver to Help Efficient PV Construction

Whether it is plain, mountain or gravel terrain, YG PV Pile Driver (solar pile driver) can provide efficient, accurate and stable piling solutions. We offer a wide range of models and support customization, suitable for all kinds of PV plant construction needs. We also manufacture the following equipment: photovoltaic pile driver, hydraulic rotary drilling rigs, guardrail pile driver and so on.

If you are looking for solar pile driver for sale, or are choosing the right equipment for solar farm pile driving project, please feel free to contact us for technical solutions and quotation! 【WhatsApp/WeChat/Phone】+86 13837115193.