As global solar energy, road construction, and light civil infrastructure projects accelerate, contractors are under increasing pressure to install foundations faster, quieter, and with guaranteed load performance.

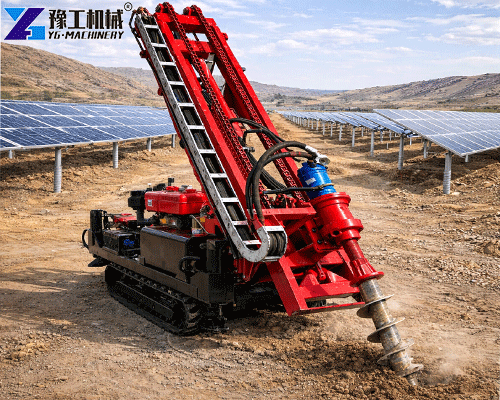

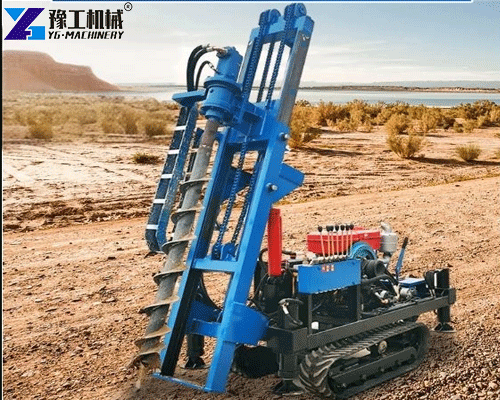

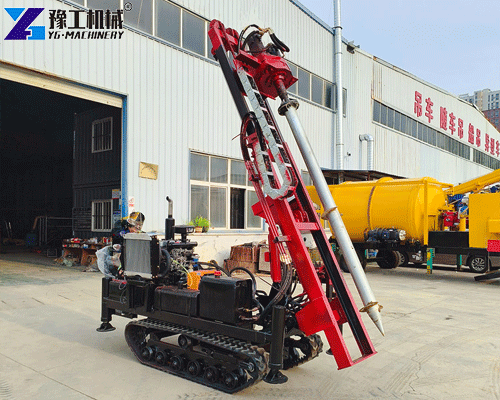

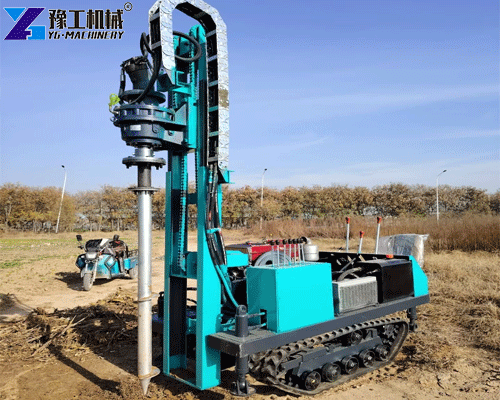

The helical pile driver (screw piling machine) has become the preferred foundation solution for projects that demand precision, speed, and minimal ground disturbance. Unlike impact or hammer-based piling, this machine installs piles through controlled rotational torque, delivering predictable results across diverse soil conditions.

Whether you are developing a solar farm, installing highway guardrails, or building modular foundations, a professional helical pile driver significantly reduces installation risk while maximizing productivity.

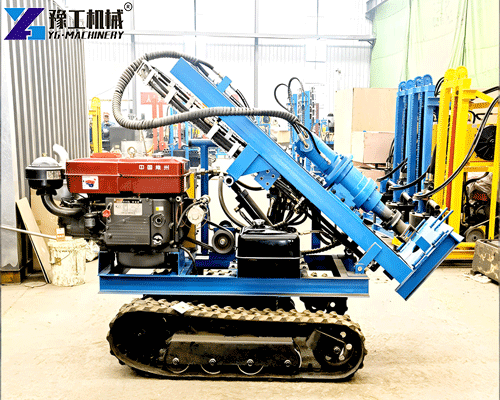

Helical Pile Driver Parameters

| Model | YG-32S helical pile driver |

| Rig weight | 1.2T |

| Dimensions (L×W×H) | 2300*1300*2200mm |

| Engine power | 32HP |

| Rotary head torque | 3500N.m |

| Hydraulic oil pump | Single pump |

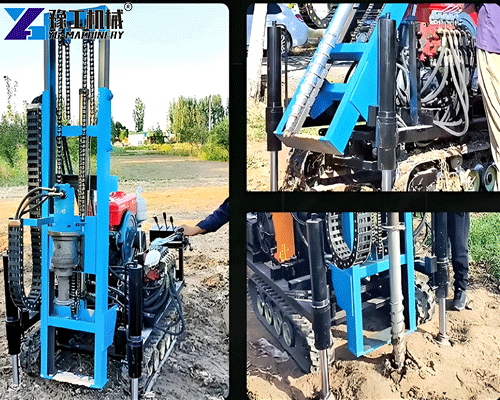

| Hydraulic loading system | Cylinder chain pressure |

| Hydraulic working pressure | 20Mpa |

| Way of walking | Crawler gearbox walking |

| Walking speed | 7-15km/h |

| Cooling system | Hydraulic cooler |

| Carriage travel distance | 2.8m |

| Piling height | 1-3m |

| Borehole diameter | 50-300mm |

| Borehole depth | 1-30m |

| Air consumption | 6m³/min |

| Adapt to rock types | Medium hard rock, F=8-12 |

| Hydraulic legs | 4 |

| Climbing ability | 35° |

Why This Helical Pile Driver Is Different?

1. Torque-Driven Installation — No Hammering, No Guesswork

This machine uses high rotary torque instead of impact force, allowing screw piles to cut into soil layers smoothly.

What this means for your project:

- No soil collapse or pile rebound

- Consistent bearing capacity

- Zero structural damage to nearby foundations

- Approved for vibration-sensitive zones

This makes it especially suitable for solar PV projects near residential or coastal areas, where hammer piling is restricted or rejected.

2. Designed Specifically for Solar Ground Screws

Many piling rigs are “general-purpose.”

This one is engineered around solar mounting systems.

Key advantages for solar contractors:

- Accurate verticality ensures perfect alignment of PV brackets

- Adjustable piling depth matches different ground screw specifications

- Fast repositioning across large solar farms

- Ideal for both fixed-tilt and tracking solar systems

If your business focuses on solar pile foundation installation, this is not an optional upgrade—it’s a competitive advantage.

3. Outstanding Performance in Soft & Mixed Soils

Traditional piling struggles in:

- coastal soil

- clay and silt

- backfilled or loose ground

This helical pile driver excels exactly in these conditions.

Thanks to controlled torque and hydraulic pressure:

- piles remain stable during installation

- bearing layers are reached without over-drilling

- foundation integrity is significantly improved

That’s why contractors increasingly replace impact piling with screw pile drivers for PV solar farms.

4. Low Noise, Low Vibration — High Approval Rate

Urban projects and EU-regulated sites often impose strict limits on:

- vibration

- noise

- ground disturbance

This machine operates quietly, making it suitable for:

- residential-adjacent solar plants

- highway guardrail retrofits

- telecom and utility foundations

More approvals = fewer delays = faster project delivery.

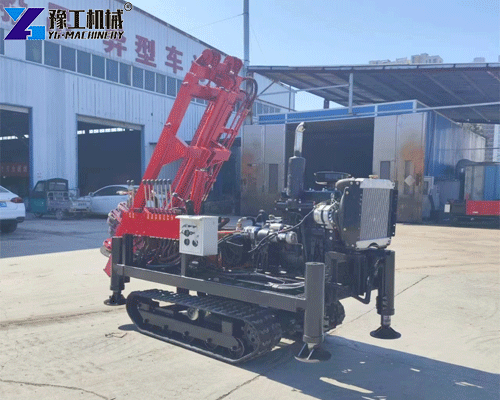

5. One Operator, High Output — Reduced Labor Cost

With crawler mobility and hydraulic automation:

- one operator can complete piling independently

- setup time is minimal

- fuel consumption is low

Compared with traditional piling methods, overall foundation cost drops sharply, while daily output increases.

For contractors bidding competitive EPC or solar projects, this directly improves profit margins.

Common Applications of the Helical Pile Driver

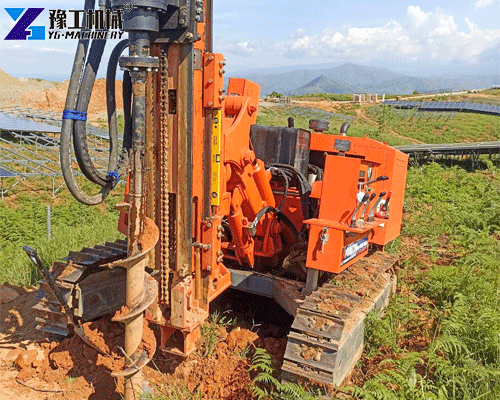

- Solar Farm Foundations: Helical piles provide stable support for ground-mount photovoltaic systems, especially in soft or uneven terrain.

This makes the equipment a perfect match with your existing solar pile driver fleet. - Highway Guardrail Installation: The machine ensures rapid, accurate installation without disrupting traffic with excessive vibration.

- Residential and Commercial Foundations: Light steel structures, modular buildings, and container homes rely heavily on screw piling for long-term stability.

- Telecom Towers and Utility Facilities: Helical piling enables deep anchoring for towers and power line supports without needing large drilling rigs.

- Disaster Reconstruction Projects: Fast deployment makes it ideal for emergency bridges, temporary housing, and rapid infrastructure setup.

Case Study: Helical Pile Driver Delivered to Spain

In early 2025, a civil construction company in Valencia, Spain, undertook a coastal solar farm expansion project.

The challenging part: the site consisted of soft marine soil, where traditional hammer piling caused excessive vibration and poor stability.

After evaluating multiple solutions, the contractor selected a YG helical pile driver equipped with high-torque rotation and an enhanced hydraulic system.

Results After Deployment:

- Installation efficiency increased by 280%, reducing the overall construction timeline.

- Pile stability improved significantly, especially in soft coastal layers.

- Noise levels dropped, allowing the project to continue near residential zones without complaints.

- The contractor was satisfied enough to place a second order for an upcoming wind-farm reinforcement project.

This project proved that the helical piling system is a perfect fit for European construction standards, especially where environmental restrictions are strict.

Why Choose YG Machinery as Your Supplier?

- Professional Manufacturing & Global Export Experience: YG Machinery has provided piling equipment to over 20 countries, including Spain, the Philippines, Chile, and Saudi Arabia.

- Custom Solutions for Different Pile Types: Whether you need torque-focused screw piling, impact piling, or drilling-based piling, we can customize the complete solution.

- One-Stop Supporting Equipment: You can upgrade your project efficiency further with our related machinery: solar pile driver, etc.

- Competitive Pricing & Fast Delivery: We offer factory-direct prices and quick shipping from our manufacturing base.

Helical Pile Driver in YG Machinery

A helical pile driver is more than just a piece of equipment—it is a long-term solution for faster, more stable, and more efficient foundation work. Whether you are working on solar farms, guardrails, modular structures, or telecom towers, a high-quality screw piling system helps you achieve lower costs, higher efficiency, and reliable performance.

If you are searching for a durable and high-performance helical pile driver for sale, YG Machinery is ready to support your next project. Contact us to know more details now!【WhatsApp/WeChat/Phone】+86 13837115193.