Reinforced concrete cutting doesn’t need to be messy, slow, or destructive. The hydraulic wall saw is transforming structural renovation and concrete demolition projects. With unmatched cutting power, high safety standards, and environmental compliance, this tool outperforms conventional methods in every way.

YG’s Hydraulic Wall Saw Parameter

These specs make our hydraulic concrete wall saw not only more efficient but also longer-lasting in high-load environments.

| Hydraulic Oil Pump | Model | YG 600 | YG 700 |

| Max. power | 25KW | 30KW | |

| Motor cooling method | Air cooling | water cooling | |

| Rated voltage | 380V 50HZ | 380V-420V 50HZ-60HZ | |

| Pressure stages | 3 | 3 | |

| Max. operating pressure | 200bar/20Mpa | 210bar/21Mpa | |

| Oil flow rate | 30-80L/min | 40-100L/min | |

| Dimensions | 600mm*650mm*1050mm | 500mm*520mm*1100mm | |

| Weight | 220kg | 140kg | |

| WallSaw | Saw blade diameter range | 800-1400mm | 800-1600mm |

| Cutting depth | 620mm | 730mm | |

| Max. working pressure | 180bar/18Mpa | 200bar/20Mpa | |

| Max. oil flow rate | 100l/min | 100l/min | |

| Gearing | Gear | Gear | |

| Rotation speed | 450/950/1300Rpm | 450/850/1200Rpm | |

| Dimension | 400mm*420mm*400mm | 400mm*420mm*400mm | |

| Weight | 38kg | 39kg |

Real-World Applications: What the Hydraulic Concrete Wall Saw Excels At?

Whether you’re cutting through bridge pilings or modifying building structures, YG’s wall saw handles it all.

Case 1: Bridge Deck Demolition in Canada

Using the hydraulic concrete wall saw, a team completed a 150m² concrete removal project in half the expected time, with no structural vibration—a key requirement near an active highway.

Case 2: Door and Vent Openings in Industrial Walls (Saudi Arabia)

Contractors needed to retrofit large vent systems into 600 mm-thick factory walls. Our saw’s cutting depth and precision prevented any damage to nearby equipment.

Case 3: Subway Renovation in France

The concrete wall saw for sale from YG was used to expand emergency exit routes in an underground subway, where space was tight and vibration control was critical.

These examples prove the wall saw’s versatility across industries: transportation infrastructure, energy facilities, commercial buildings, and more.

Purchase Guide

When selecting a hydraulic concrete wall saw, don’t be misled by surface specs alone. Evaluate based on real-world needs:

- Depth Accuracy in Dense Materials: Confirm blade diameter and actual cutting depth vs pressure drop at max load.

- Cooling Type Based on Usage Duration: Air-cooled for short jobs, water-cooled for extended cutting sessions.

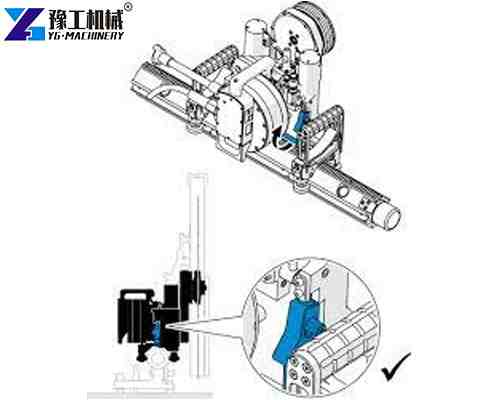

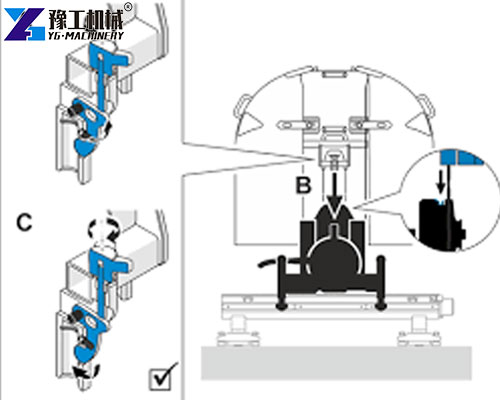

- Track and Mounting System Compatibility: Check if the saw can be securely installed in vertical, horizontal, or overhead conditions.

- Safety Features: Look for overload protection and emergency shut-off systems.

These factors determine not just cutting quality, but the machine’s reliability and your team’s safety.

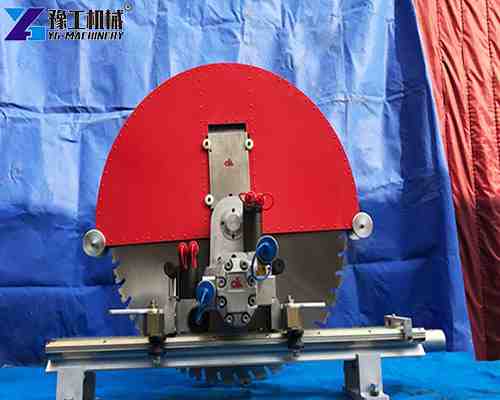

Simplified Working Principle

The hydraulic concrete wall saw works through a dual-system setup:

- Hydraulic Power Station generates pressurized oil (up to 210 bar)

- This drives the saw head, which runs along a rail, spinning a diamond saw blade

- The saw moves in a straight line, cutting through concrete with minimal dust or vibration

This setup allows clean, static cutting without compromising structural integrity.

Why Choose YG Machinery?

YG Machinery’s hydraulic wall saws are trusted across over 15 countries for their reliability, cutting power, and service support. As a professional manufacturer, we don’t just sell machines—we provide cutting solutions tailored to your site and technical needs. Contact our team for expert guidance and get a free quote today. Let YG help you cut faster, cleaner, and safer. In addition, we offer: diamond wire saw machines, electric wall saws, hydraulic rock breaker machine, concrete pile breakers, excavator hydraulic shears, etc. Contact us via WhatsApp/WeChat/Phone/Skype: +86 13837115193. Get a free quote now and elevate your concrete cutting capabilities!